PRODUCTIVITY OF $4,000-5,000 MOWERS

Whether it is a zero-turn mower or a lawn tractor, most mowers in this price range have 48- to 54-inch cutting decks and top speeds of 6-7mph. As a result, the raw productivity numbers are fairly similar in this category, but in reality, the differences in maneuverability are greatest in this price range. That’s because lawn tractors in this category don’t offer maneuverability-enhancing features such as four-wheel steering. On the other hand, the Exmark Quest S-Series is a true zero-turn mower, with the ability to quickly make 180-degree turns. This not only lets you maximize productivity, but also create the distinctive striped appearance that’s the calling card of a professionally maintained lawn.

Whether it is a zero-turn mower or a lawn tractor, most mowers in this price range have 48- to 54-inch cutting decks and top speeds of 6-7mph. As a result, the raw productivity numbers are fairly similar in this category, but in reality, the differences in maneuverability are greatest in this price range. That’s because lawn tractors in this category don’t offer maneuverability-enhancing features such as four-wheel steering. On the other hand, the Exmark Quest S-Series is a true zero-turn mower, with the ability to quickly make 180-degree turns. This not only lets you maximize productivity, but also create the distinctive striped appearance that’s the calling card of a professionally maintained lawn.

An Exmark Quest S-Series zero-turn rider with a 50-inch cutting deck is capable of cutting approximately 2.8 acres per hour, or roughly 1/2 acre more per hour than an X320 lawn tractor with a 48-inch cutting deck. Even when you bump up to a 54-inch cutting deck, the X320 is still about .2 acres per hour less productive than the zero-turn machine.

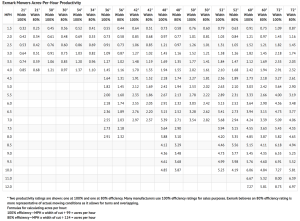

See the productivity chart for these mowers at Exmark.com.

PRODUCTIVITY OF $7,000-8,000 MOWERS

Raw productivity numbers for machines in the $7,000-8,000 price range jump roughly one acre per hour for ZTRs, and one-half acre per hour for lawn tractors, when compared to the lower priced mowers. Within the category, the most productive machine – a 60-inch Exmark Pioneer S-Series zero-turn rider – can save homeowners about 23 minutes when mowing five acres, compared to the lawn tractor example.

Raw productivity numbers for machines in the $7,000-8,000 price range jump roughly one acre per hour for ZTRs, and one-half acre per hour for lawn tractors, when compared to the lower priced mowers. Within the category, the most productive machine – a 60-inch Exmark Pioneer S-Series zero-turn rider – can save homeowners about 23 minutes when mowing five acres, compared to the lawn tractor example.

Similar to the lower price category, the majority of lawn tractors in this price range steer with the front wheels only. This compromises productivity due to reduced maneuverability relative to zero-turn riding mowers. The Pioneer S-Series zero-turn rider offers true zero-turn maneuverability, making the real-world productivity gap even greater when compared to a lawn tractor.

For example, and Exmark Pioneer S-Series zero-turn mower with a 52-inch cutting deck is capable of cutting about 3.35 acres per hour. The same mower equipped with a 60-inch cutting deck can mow up to 3.87 acres per hour. When compared to a similarly priced lawn tractor (an X540) with a 54-inch cutting deck, the 60-inch Exmark zero-turn mower is nearly 3/4-acre per hour more productive.

Check back for our next installment of this series on Thursday, January 14. We’ll compare the productivity of $13,000-14,000 mowers and dive into some other factors to consider when choosing the right type of mower for your lawn.

Dig Deeper at Exmark.com:

- Learn more about the factors to consider when choosing a zero-turn mower or lawn tractor.

- Learn more about how to determine mower productivity.

*Productivity rating in gross acres per hour is based on the published specifications for each product. Actual performance may vary from specified performance based on conditions.

Formula for calculating acres per hour at 80% efficiency: (MPH x width of cut in inches)/124