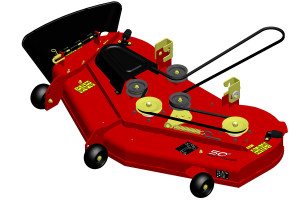

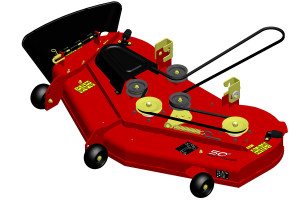

The Exmark Series 2 fabricated cutting deck delivers increased strength, stiffness and durability compared to stamped deck designs.

Exmark has upgraded the cutting decks available on the 2016 Quest E-Series zero-turn riding mower. Customers can choose from 42- or 50-inch Series 2 welded, fabricated cutting decks, in addition to the 42-inch Series 1 cutting deck that was standard in 2015.

“We’re always looking for ways to increase the performance and value of our mowers,” said Exmark Director of Marketing, Daryn Walters. “We want even our most affordable model to offer commercial features such as a fabricated deck.

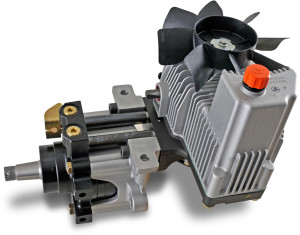

The Exmark engines that power Quest mowers are designed to be strong-running, durable and easy to service.

“Look at the mowers the pros are using, and they’re all running welded, fabricated decks. It’s because they’re stronger, stiffer and more durable long-term.” In addition to welded, fabricated construction, the Series 2 cutting decks feature durable, zero-maintenance sealed spindles designed to deliver a lifetime of reliable performance. The single-point height adjustment system makes cutting height easy to set or adjust, and the full-floating deck design ensures scalp-free mowing.

The Quest E-Series mowers feature Exmark power – the 708cc twin-cylinder engine on 50-inch models, and the 452cc single-cylinder powerplant on 42-inch machines. Designed from the ground up as zero-turn mower engines, both engines offer responsive, reliable power, with quicker governor response to deliver more power precisely when it’s needed.

Enhanced safety is provided by an automatic braking system, which applies the parking brake automatically whenever the controls are positioned outward. The standard 18-inch extra-tall back seat features suspension for a smoother ride.

The Quest S-Series is available with a choice of a steering wheel (shown), or traditional twin-stick controls.

In addition to the Quest E-Series, Exmark offers the Quest S-Series mower in 34-, 42-, and 50-inch models. The Quest S-Series features a number of drive system upgrades, as well as an upgraded 18-inch Deluxe seat with a bolstered design and suspension system for increased operator comfort. Available with a choice of traditional stick-based controls, or in a steering wheel-equipped Front Steer model, the Exmark Quest S-Series delivers more professional grade features in a residential riding mower.

Learn more about Exmark’s 2016 family of Quest zero-turn riding mowers, or locate your local Exmark dealer at Exmark.com.