This is the time of year when a lot of folks are starting to think about warmer weather and getting out into the yard. For those looking to upgrade their equipment this season, Exmark has a number of special offers that can make it easier than ever to put the best mowers and lawn care equipment in your garage.

For a limited time, put that new Lazer Z you’ve always wanted into your garage for as little as $8,499 MSRP. (Dealer sets final retail price. Shown with available accessories: MSRP $10,071.99.)

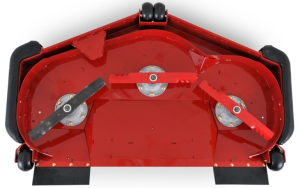

The Lazer Z E-Series is one of our most popular commercial zero-turn riding mowers. For a limited time, you can save up to $1,100 on select Lazer Z E-Series models. For example: you can take home a 52-inch Lazer Z E-Series machine (LZE732GKC524A2) for an MSRP of just $8,499, or a 60-inch model (LZE742GKC604A3) for $8,999. Visit your local Exmark dealer today to learn more or to schedule a demo.

We’re also offering rebates on select Exmark mowers, including:

- $1,000 instant rebate on Navigator riding mowers — expires April 30, 2016

- $600 instant rebate on Pioneer E- and S-Series mowers — expires June 30, 2016

- $500 instant rebate on Vantage stand-on riding mowers — expires June 30, 2016

- $100 instant rebate on Commercial 21 walk-behind mowers — expires June 30, 2016

Visit Exmark.com/Special-Offers to see these and other special offers on Exmark machines available for a limited time.

Finance Options

Step up to full commercial performance and get a $100 instant rebate when you buy the popular Commercial 21 walk-behind mower through June 30, 2016.

Exmark partners with several national lenders to offer customers financing with very competitive terms. See your local Exmark dealer for full financing details, but some examples of financing offers currently available through our lending partners include:

- 0% monthly interest for 42 months on purchases of $1,500 or more with your Exmark card — On Purchases of $1500 or more on Exmark Equipment with your Exmark credit card made between now and 04/30/2016. A $125 Promotion Fee will be charged. 42 Equal Monthly Payments required.

- No monthly interest if paid-in-full within 12-months — On qualifying purchases of $400 or more with your Exmark credit card made between now and 04/30/2016. Monthly interest will be charged to your account from the purchase date if the promotional balance is not paid in full within 12 Months. Minimum Monthly Payments required. A $50 Promotion Fee will be charged.

See full details and disclosures for these and other financing offers at Exmark.com/Special-Offers (click “View Financing Options”).