State-of-the-art Exmark EFI-propane mowers offer increased fuel economy and performance, with reduced greenhouse gas emissions.

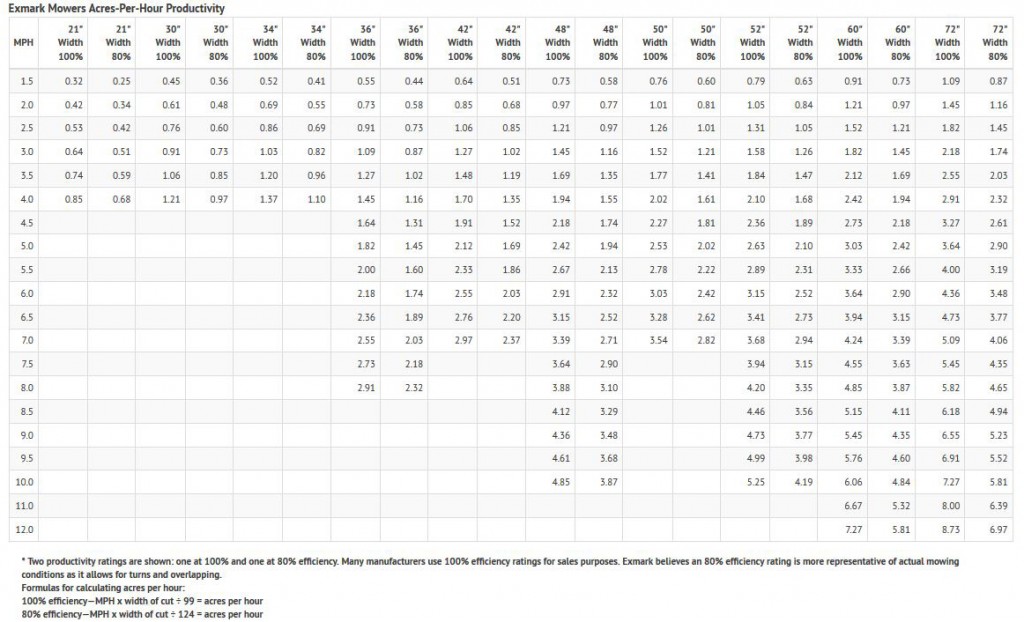

If you’re looking for ways to increase profit margins for your lawn care business, one option might be to consider switching to propane mowers. On average, it is said that about 9% of production costs for landscape professionals goes toward fuel. Therefore, a move to propane mowers regulated with Electronic Fuel Injection (EFI), could help cut your fuel costs and improve your bottom-line.

Increased efficiency — The propane engines on Exmark mowers can increase fuel efficiency by up to 40% for extended runtimes, compared to traditional gasoline-powered mowers. At the same time, historical prices for propane run about 30% less than gasoline. With gasoline prices still low, this may not seem crucial – but if there’s one rule of gasoline prices, it’s that eventually, they always go back up.

EFI with E-Gov technology plays a big part in the efficiency of propane mower engines. Electronic Fuel Injection and E-Gov keep fuel flowing to your engine at a steady rate, even when your mower revs. This prevents engine drop-off when you hit a rough patch or tackle a steep grade. Gasoline mowers with mechanical regulators can be slow to respond to increased demand on the engine. Just as when you drive, an engine that runs at steady rate performs better than one that continually revs up to work harder.

Cleaner and Greener — Propane is remarkably stable over time, and can be stored for long periods. It also burns cleaner than gasoline, reducing build-up and engine maintenance. This means less mower downtime to have your machine in the field longer, and more profit. Another added benefit is lower emissions, which has become more of a selling point with customers.

Quieter — Propane mower engines are quieter to operate than gasoline or diesel mowers, which could let you start earlier and work later than competitors, and reduce the potential for noise complaints from neighboring properties.

For more information on switching your fleet to propane, see Exmark’s whitepaper, or talk to an Exmark dealer near you.