As the calendar moves from summer to fall, it makes sense to turn your attention to maintaining your mower. Proper maintenance is essential to the longevity and performance of any mower, and proper service ahead of extended storage ensures the performance you enjoyed this season will carry forward to the next.

A focus on fall maintenance helps you get a quick, trouble-free start next spring.

Start clean

It’s important to start a period of storage with a clean mower, as any debris left on the mower will either trap moisture or become fodder for a rodent nest. It’s also easier to inspect and perform necessary service prior to storage when you’re not working through a thick layer of dust and debris.

Never use solvents to clean your mower, and minimize the use of water as well. Instead, use compressed air or a leaf blower, and finish by wiping the exterior surfaces with a damp cloth. Take your time and clean the mower completely, including under the seat, under the deck, behind the wheels and around the engine and drivetrain.

Examine Your Machine

Refer to your owners manual or to Exmark.com for information about specific service schedules, but once your mower is clean, inspect it for clear signs of wear and tear and replace any parts that are at the end of their life cycle. Checking and servicing or replacing normal wear items such as belts, tires, blades and other parts restores mower performance and ensures safety and long life. Plus, replacing worn parts prior to storage gives you the opportunity to get a quick start on the next season, as your focus won’t be distracted by service related issues.

Pay particular attention to normal wear items during your mower inspection, such as the condition of blades and deck drive belts.

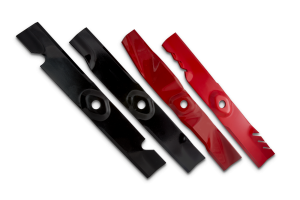

Sharpen Blades

The efficiency and quality of cut your mower delivers is highly dependent on sharp blades for top performance. After a hard season of mowing, it makes sense to sharpen your blades. In doing so, you can be confident your mower will hit the ground running when it comes out of storage in the spring.

Focus on Fuel

Extended storage can wreak havoc on an unprotected fuel system, so prior to storage it’s important to either drain the fuel tank (and system) completely, or add stabilizer to the fuel. If you go the fuel stabilizer route, be sure to run the engine for a few minutes after the stabilizer is added. This will distribute the treated fuel throughout the fuel system to keep it clean and deposit free during storage.

Remove the Battery

When storing a mower for extended periods, it’s a good idea to remove the battery from the machine and store it in a climate controlled area (preferably at 50-70 degrees F). Not only will this preserve battery condition, it will ensure that a leaking battery doesn’t cause corrosion to the mower frame during storage. Learn more about caring for batteries in this post from Exmark’s David Martin.

Fresh Lube is Good

Lubrication is the life blood of your mower, and it’s important to refresh all lubricants prior to extended storage. This includes changing the engine oil and filter as well as the hydro (drive) fluid and filter, and greasing all zerk-equipped bearings on the machine.

Replace both engine and hydro oil and filter(s) prior to extended storage.

Take your time when lubricating your mower, as it’s important to remove any load or binding from bearings being greased. This ensures lubrication reaches the entire bearing instead of just a portion of it. Also, inspect bearings for wear and/or play, and replace any bearings that have been compromised in any way.

Storage Considerations

Regardless of where you store your mower — in a barn, under a waterproof tarp, or in an inclosed trailer — it’s just as important to keep rodents at bay as it is to keep the elements out. There are a variety of traps and chemicals to choose from, and natural solutions such as oil of peppermint or Osage oranges can also be effective at keeping your machine free of vermin. It’s important to avoid the use of harsh chemicals on your machine, as many can cause damage to its finish, or to specific components. Your local Exmark dealer can be a good resource for suggestions to control rodents specific to your area.

Keeping moisture at bay is equally important. Store your mower in a place where snow, rain and ice can not reach it. Rust can appear quickly on stored machines left out in the elements, so keeping your mower in a well-protected place preserves not just its longevity, but also its performance.

Learn more mower service tips at http://www.exmark.com/ServiceTips.aspx. Locate the service schedule for your Exmark machine at http://www.exmark.com/MaintenanceSchedules/.