At Exmark, we understand the importance of making sure your lawnmower is in tip-top shape in preparation for the upcoming landscaping season. One of the top maintenance items for any rotary mower is to ensure blades are properly sharpened, balanced and in good working order.

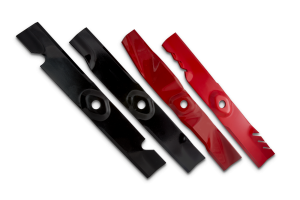

Sharp, balanced blades are an essential component of cut quality. Exmark offers a variety of blades to optimize performance for different cutting conditions.

Why Sharp Blades Matter

When you are shaving your face in preparation for the day, think about the difference between the times you use a brand-new razor blade and the times you are trying to get one last shave out of an old blade. When using an old blade, your skin is more prone to cuts, infection, and irritation. When using a brand-new blade, you get a nice, clean shave.

The same thing happens with your grass. If the blades are dull or nicked, the lawn will get cut in a ragged way, causing it to suffer damage and become more susceptible to pests and other diseases. But if the blades are nice and sharp, the grass will get a clean cut, with greatly reduced damage or stress.

Blade Inspection

At the beginning of the landscaping season (and after roughly 8-10 hours of service) do a thorough inspection of your mower’s blades. Signs of a dull blade include bends, nicks, and/or dents. You’ll want to ensure the blades are properly sharpened and balanced. In addition to the physical inspection of the blades, do a quick inspection of the lawn before you begin your landscaping — clear away any rocks, sticks, or other debris in the immediate area. As you mow, keep an eye out for these blade-nicking items.

Properly Sharpening Your Blades

Keep in mind these few basic tips for sharpening your blade:

- Wear protective gear, such as safety glasses

- Disconnect the spark plugs

- Remove the blade (instructions are found in your owner’s manual)

- Use a metal file or sharpening stone

- If using a file, run it in the direction of the blade’s angle — never file back and forth

- Work in one direction only; blades usually have an angle of 45 degrees

- Consult your owner?s manual for procedures specific to your mower

Depending on usage, replace your lawn mower’s blade(s) every 1-3 years. Always use OEM blades designed for your specific mower. Universal blades may save you a couple dollars, but can cause potential safety issues from improper mounting and/or the type of metal used to construct the blade.

Properly Balancing Your Blades

Having properly balanced blades is every bit as important as blade sharpness. An unbalanced blade causes stress on the engine and cutting deck due to vibration.

After you sharpen the blade, test its balance with a blade-balancing tool. If you don’t have access to this specialized tool, you can hammer a nail partway into a wall in your garage and hang the blade from it (using the center hole). If the blade hangs horizontally, it is in balance. If one side drops, remove excess material from the side it leans to, using a file or sharpening stone.

Professional Sharpening

If you follow these recommendations and have the proper tools and safety gear on-hand, sharpening your blades is a relatively easy task. However, if you don’t have the proper gear, or don’t feel comfortable doing this type of maintenance yourself, your local Exmark dealer can quickly sharpen and balance blades for you.

Bottom line: using sharp blades will help you have a perfectly mowed lawn, every time.

Resources: