Commercial mowers have been available with engines using Electronic Fuel Injection (EFI) for nearly a decade. Yet despite their performance and fuel efficiency advantages, some landscape professionals still haven’t made the switch from mowers powered by carbureted powerplants.

Advantages of EFI

At a glance, it’s hard to tell an EFI-equipped engine from a carbureted model, but the gains in fuel efficiency and performance are easy to see, and appreciate.

Every modern automobile and truck engine uses EFI to deliver increased performance and fuel efficiency in a wider range of conditions, along with reduced emissions of greenhouse gasses.

EFI-equipped engines are capable of adjusting the fuel/air mixture to optimize performance in the conditions the mower is operating in. Factors such as altitude and temperature, among others, are measured continually, with adjustments to engine settings being made instantly, seamlessly, in real time.

See how Birchwood Snow & Landscape simultaneously saves money and makes more money with their Kohler EFI-powered Exmark Lazer Z mowers.

A carbureted engine lacks the capability to self-adjust for varying environmental conditions, so performance is virtually always compromised in one way or another. In order for the engine to not run too lean (too little fuel) at low elevations, it’s performance will suffer from too much fuel (running rich) at higher elevations. It’s a situation that can be compensated for by re-jetting the carburetor (typically done by a service technician). However, when EFI can make these adjustments on-the-fly, it’s easy to see the benefits with respect to performance, as well as lack of down time and service costs.

The Cost Factor

Some contractors cite the increased up-front cost of EFI-equipped mowers, which is typically $500 to $600 more than a carbureted equivalent. When you do the math however, it’s easy to see the switch can quickly be paid off by the fuel saved with EFI, but the performance and efficiency benefits continue throughout the life of the powerplant.

According to Kohler Engines, a simple switch to an equivalent EFI powerplant will typically reduce fuel consumption by 25-percent or more. Assuming a per gallon price of $3.00 for gasoline, the cost of an EFI-powered mower can be recouped in as little as one season for a typical landscape contractor. See how much money you could save with EFI.

Exmark’s Vantage S-Series Propane brings EFI propane advantages to commercial stand-on riding mowers.

EFI Propane Engines

Exmark also offers the industry’s widest range of propane-fueled mowers equipped with EFI, with Lazer Z (zero-turn), Turf Tracer (walk-behind) and Vantage (stand-on) models available. Exmark propane mowers feature state-of-the-art Kohler Command Pro EFI-propane engines, which can reduce fuel costs by up to 25-percent when compared to converted carbureted propane engines.

Combine the EFI-related fuel savings with the fact that propane typically sells for much less than gasoline during the cutting season and it’s easy to see why EFI-propane mowers are a compelling choice for a growing number of landscape professionals. Plus, propane mower incentives are available from the Propane Education and Research Council (PERC), which can reduce the up-front costs of a propane-fueled machine.

RED Technology

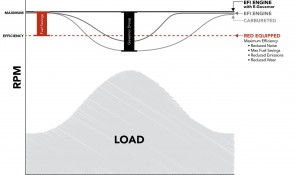

The electronic governor of a RED-equipped engine responds more quickly than mechanical governors, so RPM is maintained more consistently regardless of engine load.

In 2013, Exmark took the efficiency gains of EFI-equipped mowers to another level with the introduction of its patented RED Technology. An exclusive feature of the Exmark Lazer Z X-Series zero-turn rider, RED Technology pairs EFI with an electronic governor and an intelligent engine controller to deliver fuel efficiency gains of up to 40-percent compared to equivalent carbureted gasoline-fueled machines.

Assuming a per gallon price of $3.00, the fuel savings of a RED-equipped machine can pay off the increased up-front cost of approx. $700 very quickly — in less than one season for most landscape professionals. But the fuel efficiency and performance benefits will remain consistent well after the up-front cost has been recouped.

Learn more about the advantages of EFI- and RED-equipped Exmark mowers at Exmark.com/Exmark-Advantage/.

SHARE