Exmark now offers 72-inch versions of its Lazer Z E-Series commercial zero-turn mower. The wider cutting deck – available in side- or rear-discharge configurations – delivers maximum productivity to make short work of large mowing jobs.

The Lazer Z E-Series is available with a choice of rear-discharge cutting decks in 60- or 72-inch cutting widths, or side-discharge decks in 48-, 52-, 60-, or 72-inch cutting widths.

“The Lazer Z E-Series is a great choice for professional landscape contractors who keep a keen eye on the bottom line, but understand the value of the innovative engineering and commercial-grade quality of a Lazer Z,” said Exmark Director of Marketing, Daryn Walters. “It strikes a perfect balance of value, productivity and performance.”

With the same welded, heavy-duty tubular steel unibody frame found throughout the Lazer Z line, the Lazer Z E-Series machine is built to stand up to years of tough commercial use. The simplified hydro drive system uses Exmark-exclusive Parker unitized pump and wheel motor systems with no hoses to leak and just two easy-to-change belts.

The 72-inch Lazer Z E-Series models are equipped with a twin-cylinder Kawasaki FX801V powerplant. Designed specifically for commercial mower applications, the engine features a heavy-duty dual-stage canister air filtration system, cast-iron cylinder liners, pressurized lubrication with high-efficiency oil cooler, and a heavy-duty shift-type starter.

Rear-discharge models are equipped with the UltraCut Rear Discharge cutting deck in a choice of 60- or 72-inch cutting widths.

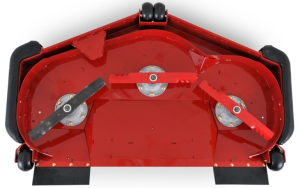

Side-discharge models are equipped with Exmark’s UltraCut Series 4 cutting deck in a choice of 48-, 52-, 60-, or 72-inch cutting widths. The 5.5-inch deep UltraCut Series 4 deck features Exmark’s patented flow-control baffles optimize air and clipping flow to maximize cut quality. Formed and welded 7-gauge steel reinforcement rings on top of the deck to provide superior strength and durability, while sealed, non-greasable spindles and patented spherical bearings on the idler arm pivots minimize necessary maintenance.

Check out special offers on select Lazer Z E-Series mowers at Exmark.com/Special-Offers, or locate your local Exmark dealer at Exmark.com.